Heat Recovery Project

Waste Heat Boiler Heat Recovery Technology

The waste heat recovery boiler heat recovery technology in the NEUEET Heat Recovery Project mainly uses the waste heat in the waste gas, waste materials or waste liquid in various industrial processes to produce energy such as steam and hot water. And it is often coupled with ORC waste heat power generation, combined cooling, heating and power and other technologies.

Organic Rankine Cycle (ORC) Waste Heat Recovery Technology

The Organic Rankine Cycle (ORC) is a Rankine cycle with low-boiling organic matter as the working medium, which can obtain a high steam pressure at low temperature and push the expander to do work, thereby converting low-grade thermal energy into high-grade mechanical energy and electrical energy. It is often used in the industrial field to recover medium and low temperature waste heat for power generation.

Types of waste heat recovered: low-pressure steam, flue gas, hot water, etc.

Temperature requirement for waste heat: ≥150°C

Areas of Application

Petrochemical Industry

Waste heat of steam in oil production site, condensation after hydrocarbon fractionation, and the waste heat of combustion unit of natural gas long-distance pipeline.

Non-ferrous Metal Industry

Waste heat generated by electrolytic aluminum cooling flue gas.

Iron and Steel Industry

Waste heat of sintering line, gasification cooling process of converter, flue gas and resumption of steam production of heating furnace, waste heat of saturated steam generated by dry quenching, and waste heat of blast furnace slag flushing water.

Thermal Power Plants & Printing and Dyeing Plants

Technical Advantages

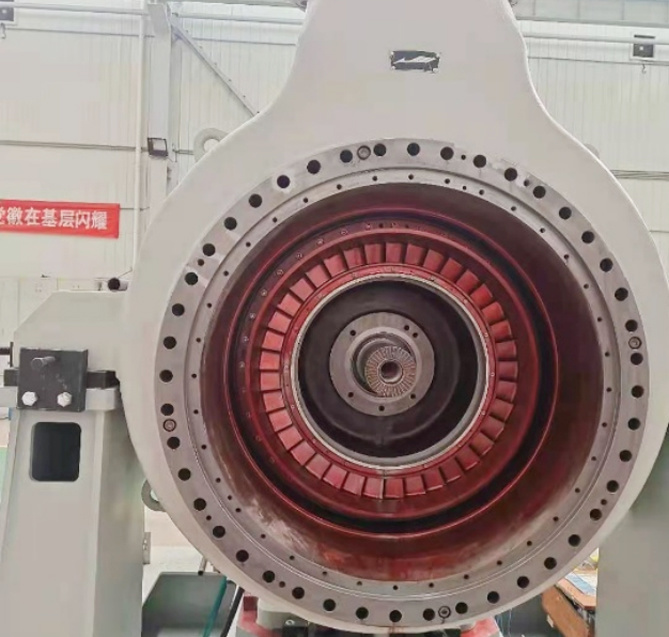

The third-generation maglev motor independently developed by NEUEET has achieved a breakthrough in critical speed. It can also achieve online monitoring and real-time control of the system maglev shaft system. When NEUEET maglev motor is applied to ORC power generation system, it does not need the shaft seal gearbox and coupling in the traditional system, and the efficiency is increased by 25% compared with the traditional ORC system, which can greatly shorten the payback period.

Actual Picture

Project Examples

An Energy Company in Jiangsu

The energy company's ORC power generation project has an installed capacity of 5MW, which is currently the largest ORC generator set in China, with an investment of 50 million yuan, a payback period of 2.5 years, saving 10,158 tons of standard coal and reducing carbon dioxide emissions by 25,395 tons/year.